FlackTek™: How a 1960s Patent Led to the Future of Materials Processing

Discover FlackTek's MEGA innovation: high-speed bladeless mixers driving precision, scalability, and sustainability in modern materials processing.

GERMANY, January 30, 2025 /EINPresswire.com/ -- – Materials processing has come a long way since its early days, evolving from niche solutions to transformative technologies that drive industries forward. At FlackTek™, our journey is rooted in tradition, while embracing new possibilities. As we reflect on our history, we’re also celebrating recent milestones, including the MEGA FlackTek, the world’s most sophisticated and largest high-speed bladeless mixer which delivers an impressive capacity of hundreds of thousands of kilos.The Original

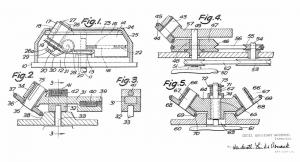

The story of dual asymmetric centrifugal materials processing began in the late 1960s in Great Britain, the original inventor being Cecil Halliday Woodham who received the first patent (US3679184) for this novel technology. His work transformed materials processing starting with the dental industry, enabling precision and efficiency that now benefits a wide range of applications today. FlackTek proudly builds on this legacy, advancing solutions designed to meet the demands of modern manufacturing, and serving everyone from aerospace to specialty chemicals, pharmaceuticals to food and beverage, and beyond.

From Silicones to Industry Leadership

FlackTek’s journey originated in the 1990s with Dale Flackett, first addressing the unique needs of silicone manufacturers, but quickly expanding to cover everything from specialty chemicals to aerospace and beyond. By the 2010s, FlackTek became a recognized leader in materials processing, with over 1,500 scholarly publications highlighting our impact on research and production processes worldwide.

Innovating to Solve Real-World Challenges

In 2019, FlackTek leaped forward with the opening of a state-of-the-art manufacturing facility just outside Boulder, Colorado. This milestone enabled flagship innovations like the MEGA FlackTek™ and proprietary systems designed to deliver unmatched precision, capacity, and efficiency. By bringing manufacturing and design in-house, FlackTek gained the ability to beat industry-standard lead times, maintain complete control over quality and support, and offer customizations to meet exact customer needs. These advancements reflect our commitment to solving customer challenges and enabling smarter manufacturing.

Beyond the GOAT: A Commitment to Continuous Progress

The MEGA FlackTek™, nicknamed the GOAT, is just one example of our drive to innovate. With its 1960s origins in dental applications to breakthroughs in aerospace and defense, FlackTek’s bladeless mixing technology demonstrates what’s possible when customer needs guide innovation. Yet, FlackTek’s focus extends far beyond the GOAT—the company is dedicated to empowering customers at every stage, from R&D to full-scale production.

FlackTek’s Vision for 2025 and Beyond

As industries evolve, FlackTek is committed to delivering precision, scalability, and sustainability. Our bladeless mixers reduce waste, eliminate contamination, and integrate seamlessly with automated systems. Innovations like the SpeedDispenser™ and advanced robotic solutions exemplify our efforts to enhance efficiency and enable sustainable manufacturing practices.

A Shared Journey of Progress

At FlackTek, innovation isn’t just about advancing technology—it’s about making a meaningful difference for our customers, allowing them to disrupt the status quo. As the company moves into 2025, it celebrates the progress made alongside its partners and advanced mixing solutions. To explore how our innovations can enhance your manufacturing processes, please visit FlackTek.com.

About FlackTek™

Headquartered in Landrum, South Carolina, FlackTek™ has been providing materials processing solutions since 1996. With a core focus on quality and performance, it strives to deliver industry-best results at every point in the mixing process. To that end, FlackTek™ offers The FlackTek™ - a high-speed planetary mixer, supplies, and accessories for all scales of needs ranging from R&D to production, in-depth training, and world-class technical support and service.

Our research, design and manufacturing is done in the U.S., out of a state-of-the-art facility located outside of Boulder, Colorado. There, they create the most advanced planetary mixers on the market by leveraging decades of materials processing knowledge and sourcing the highest quality componentry. This combination of technical expertise and high-end manufacturing is what allows FlackTek to uphold its characteristic standard of quality, and boast the world’s best support to guarantee materials processing performance that their customers rely on. FlackTeks are designed, built, and supported by people who know how to use them.

For more information log on to www.FlackTek.com.

###

Michelle Jun

FlackTek

Michelle.Jun@FlackTek.com

Visit us on social media:

LinkedIn

Distribution channels: Aviation & Aerospace Industry, Chemical Industry, Electronics Industry, Energy Industry, Healthcare & Pharmaceuticals Industry ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release